DecTek – Market Leaders in Domed Resin Products

The Mutoh LED UV direct-to-object printers meant that DecTek no longer had to print to vinyl first, but could print direct to the required plastic substrate before doming, thus eliminating the print-to-vinyl stage and reducing the dry-time.

The Challenge

To produce domed resin products and promotional items cost-effectively and quickly as part of a wider business expansion.

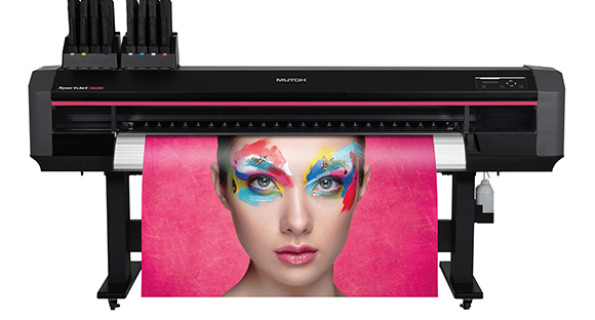

Products in user story: ValueJet 426UF LED UV and ValueJet 1638X roll to roll printer

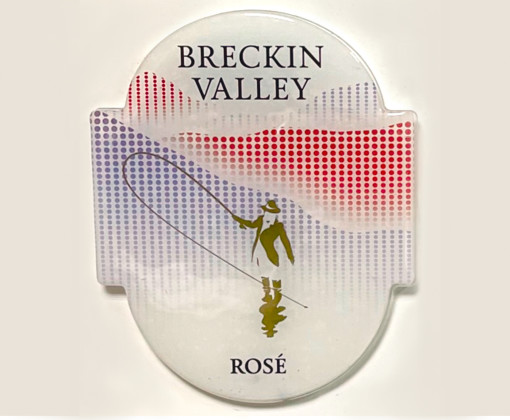

DecTek saw an opportunity to offer domed resin products such as name badges and signage following customer enquiries and market trends. At the time, the Company saw it as a small, niche addition to their established wide format print-on-demand business which would hopefully open up further opportunities for them. However, their investment in the technology to produce domed resin products changed the whole direction and future of the Company and is now their lead product group, making them the market leader in the UK.

Formed in 2001 by Managing Director, Mike Beese, DecTek is a progressive multi-award winning manufacturer of digitally printed and polyurethane resin coated products which are used for branding, marketing and advertising purposes. Manufactured from its headquarters in Pontypridd, South Wales and used by many of the world's leading brands, DecTek products continue to be used worldwide and across a multitude of different industries.

Initially, DecTek invested in several Mutoh roll-to-roll printers to produce the base design for the domed resin stickers and labels. These would then be cut out and the resin applied to the printed vinyl and then mounted to the plastic badges or other substrates before being finished.

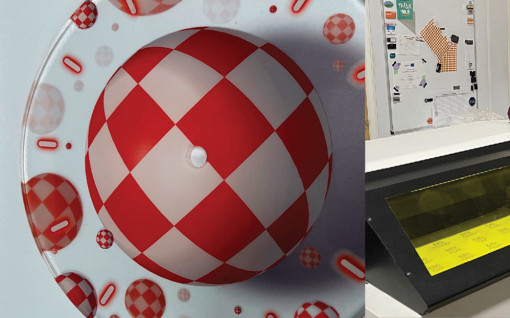

However, in 2014 Mutoh launched their flatbed LED UV printer range and DecTek immediately saw that production could be increased by investing in this technology. The Mutoh 426UF LED UV printers meant that DecTek no longer had to print to vinyl first, but could print direct to the required plastic substrate before doming, thus eliminating the print-to-vinyl stage and reducing the dry-time. This was a big step forward in production efficiency and cost.

Mike Beese notes : "Our investment in the Mutoh printers has opened up huge opportunities for us, we can sample quickly and have that on a client's desk within 48 hours. There is no complicated set up, it’s all really quick and easy and they are a great addition to our sales force. In a nutshell, the fact that we can react quickly means we are much more likely to win the business!".

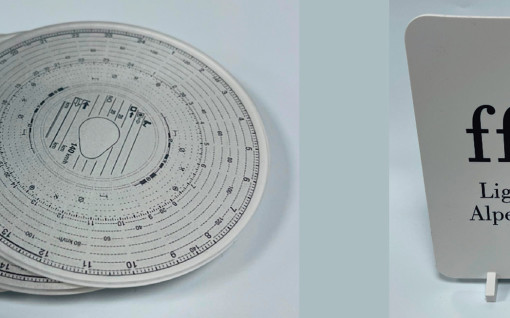

In addition to producing domed resin products, the LED UV printers also opened up the personalised promotional products market for DecTek. One of the largest leisure areas (amongst others) they supply to is the golfing sector. They produce poker chips which act as markers, tape measures, belt buckles and more. They also use the printers for the production of packaging and prototyping, especially for the cosmetics industry where look and feel are critical to a products success. As LED UV technology allows printing on to just about any substrate, DecTek can offer clients endless quality packaging solutions.

He adds : "We currently have six Mutoh printers, two ValueJet 426UF LED UV printers and four ValueJet 1638X roll to roll models. We run them all 24/7 and estimate that each one produces 1.5 million products per month. Anything from labels, posters, floor graphics, fascia panels and warning labels to our domed resin products and packaging . We’ve purchased 10-12 Mutoh’s over the years and upgrade them at the 4 year mark as newer models mean we can produce more and gain more efficiencies. Mutoh has allowed us to grow our business from a lifestyle Company to a £2mllion per year turnover Company, and we’re forecasting further growth year on year. Each Mutoh printer earns us around £0.5 million over its time with us."

Being ahead of market trends and demand is as important to DecTek as it would any market leading company and investing in new technology is key to retaining that position and growth.

Mike says : “It’s very important to continue investing in new technology, not only to keep ahead of your competition, but to be in tune with market demands and new applications and Mutoh has helped us do this”.